Toilet Paper is Good. But beware of flushable wipes.

What did they use before toilet paper? Watch this video to find out.

Many people thought flushable wipes were the next great thing. But many people have learned that “flushable” wipes often cause clogs and backups.

So while we suggest to sticking to old fashion toilet paper, we know that probably isn’t going to happen. So if you own or manage a building, facility, or plant, you should strongly consider installing a Traptex device to prevent toilet backups. The Traptex device allows toilet paper to flush, but rejects “non-fulshables” that cause all the problems.

Learn more at: https://www.drain-tech.com/clogged-toilet-drains-traptex/traptex-plumbing-protection-for-toilets/

Why your restaurants should consider a Smartpro Grease Interceptor and Alarm System

Grease traps (Grease Interceptors) are often pumped too often because pumping intervals are set using a best guess to ensure compliance. If the interceptor tank is pumped too often, clients could be paying thousands of dollars in unnecessary pumping costs. If an interceptor is not pumped often enough, there could be significant amounts of grease moving down into the sewer system creating a risk of clogs or government penalties. The SmartPro connected interceptor monitor ensures people know exactly when a tank needs to be pumped.

If a grease interceptor gets too full of solids and grease, it can cause serious problems for the restaurant and the sewer system. Some of the possible consequences are:

- Drain clogs and backups: When the grease interceptor is full, it cannot trap the fats, oil, and grease (FOG) effectively, and they can flow into the drain pipes. This can cause blockages and backups in the pipes, which can result in flooding, foul odors, and health hazards.

- Sewer overflows: When the FOG reaches the sewer system, it can accumulate and harden on the walls of the sewer pipes, reducing their capacity and causing obstructions. This can lead to sewage overflows into the environment or into other buildings, which can damage property, harm wildlife, and contaminate water sources.

- Fines and penalties: When a restaurant causes a grease-related problem in the sewer system, it can face enforcement actions from the city or the sewer authority. The restaurant may be liable for any damages caused by the sewer overflow, and may also have to pay fines or penalties for violating the local codes and regulations.

To prevent these problems, it is important to maintain the grease interceptor regularly and properly. It is generally accepted that a grease interceptor should be cleaned when it reaches 25% capacity of FOG and solids (though many engineered grease interceptors can hold much more). The cleaning should be done by a licensed professional who can follow the proper procedures and dispose of the waste safely.

But how do you know when your grease trap is at 25% capacity? That’s why you need a SmartPro! SmartPro™ is a complete line of monitoring systems – now available in wireless radio, cell network or gateway cloud connectivity. SmartPro provides visibility to a grease interceptor’s grease levels, solids, and temperature to minimize operational risk and ensure compliance.

“One JPG customer went from pumping every month for compliance to pumping every quarter based on their actual need,” says John Geiling, President and CEO, JPG Plumbing & Mechanical. “The data presents itself through the SmartPro System. At $450 dollars per pump at 200 stores, this customer could save up to $720,000 a year.”

Click here to learn more!

Does it pay off to lock down the drains in a restaurant?

The article below was originally published in the Facilitator : December/January 2022 issue.

On Lockdown

The true value of preventing plumbing-related restaurant closures with Shawn Coe, CRFP, Panda Restaurant Group

What is your current title? How long have you been with Panda Restaurant Group?

My current title is regional facility manager. I have been with Panda Restaurant Group for approximately 2.5 years.

What is your history in the restaurant industry?

I have been in the restaurant business for much of my life. My restaurant experience began in operations, and I’ve held every position from dishwasher to area director. Now in my current role I am able to support operations, having walked a mile in their shoes.

How is facilities organized at Panda? How many locations do you have?

Our Restaurant Development Department consists of four sub-departments, with real estate, design, construction and facilities. Panda Facilities is structured with directors, senior facilities managers, regional facilities managers, associate facilities mangers and support team. Team members are located throughout the country, living in a home region and supporting two or more regions with anywhere from 100 to 200 stores. I support close to 150 locations and several different concepts (Panda Express, Panda Inn, Uncle Tetsu, Ippudo and Yakiya). While the number may seem high as an FM, I am supported by our facilities support team and a number of in-house departments, and we utilize CMMS software to manage our work order process.

There are few items that could potentially shut down your restaurants like having no utilities, hot water or plumbing. What programs do you have in place to minimize plumbing issues?

Store shutdowns are something that we work hard to minimize. For hot water issues, we have implemented redundant tankless hot water heater systems. As for plumbing backups, we have been testing locking drain covers for the past two years with a goal of proactively preventing drain back-ups on the main sewer line.

What prompted the test of drain lock covers?

When I began working with Panda, I was supporting the West Los Angeles Region and noticed that I was having excessive drain back-ups. The stores in this region are older and tend to have more build-up. While we did have stores receiving regular drain jetting, the plumbers would still be pulling foreign objects out of the drains.

How many restaurants were chosen? How were the locations determined?

We partnered with operations to select 10 stores. It’s simple to pick just the opportunity stores, as we know these are the exceptions. Our thought process was to include a broad spectrum of stores: old, new, opportunity, drive-thru and end-cap locations. In the end with the 10-store test, we were able to get data from stores that represents our entire brand.

Can you share the pre-test plumbing R&M costs, on the average, for these restaurants?

The monthly plumbing drain back-up average spend over a two-year pre-install was $93.59 per store. The average cost was $267 to clear the back-up on the main grease line. The numbers do not include any sanitary line back-ups.

What was the approximate cost per store for the covers? Was there any prep work required for the drains?

The cost to implement the locking drain cover project was $950 per store. Locking drain covers were roughly $400 per store, depending on the number of drain locks needed to cover every floor sink, trench drain and three comp sink. To prep the stores, we contracted with our vendor to drain jet the main grease line to include the outline after the grease trap, mini-jet the branch lines and install the drain locks.

Who kept possession of the keys for the locking drain covers?

We decided to not give the security Torx bit to the stores, which would prevent the stores from removing the drain covers. In addition, I notified my plumbing vendors that the floor sinks would now have the drain locks and to ensure that all of their techs came prepared to service with a Torx bit.

Do you have line-jetting preventive maintenance programs in your restaurants? If so, what is the frequency of the jetting?

Our stores do have drain jetting service. Depending on the area, it can be one to three times per year. This preventive maintenance approach helps to maintain the integrity of our plumbing lines.

Where were the drains located? Approximately how many per store were included?

The drains included every floor sink, mop sink, trench drain and, in some stores, the three comp sink drains. While I believe the mop sink to be a major contributor to the drain back-ups, it was important to secure any opening. Our stores already had floor screens for each floor sink, along with a secondary removable drain cover. At first glance, that is a great practice and should prevent foreign material down the drains. Going to the store late at night or early in the morning, I noticed both would be removed to allow cleaning of the floor sink and floor screen. It’s a great sanitary practice in cleaning; unfortunately this is the root cause of the drain back-ups. I definitely saw the need to provide a solution that couldn’t be removed.

What were the goals for this test?

The goal of the test was simple: to reduce drain back-ups emergencies.

During the two-year test, did you provide periodic reporting on the results?

I provided updates to the stores, leadership team and department at the three-month, six-month, nine-month, one-year and two-year mark. I recall reviewing the numbers at the one-year mark, and the spend for the stores was roughly the same. I was including the cost to purchase and jet the lines in my figure. I was hoping for more positive numbers to share with a new region I was supporting. The regional director of operations challenged me on a call, stating that my numbers were incorrect. I didn’t understand at first, as I was attempting to defend the black-and-white numbers in front of me. Then, I realized that the results of this program don’t only show up on the R&M line on our P&L. Any store shut down impacts the store on their sales line, food cost and labor line. The regional director of operations, his leadership team and I were able to come up with a formula to discover the true value of a shut down:

Sales loss = Average response time for plumbing emergency x average sales per hour

Labor loss = Average response time for plumbing emergency + reopening time x average associates on shift x average wage

Food costs = Costs of all food on steam table (as we have to discard)

True costs = Sales loss + labor costs + food costs + plumbing costs

What were the results of the test in regard to plumbing R&M and store shutdowns?

After two years of running the test and utilizing the true costs value, I can really say this program was a success. Our actual drain back-ups and shutdowns were reduced by 59.63%. When we factor the savings of the true costs, these 10 test stores were saving in the tens of thousands each year. There is an additional cost saving not discussed that should be considered an added benefit with the project: When technicians snake/cable our lines, eventually it will ultimately lead to a broken P-trap. We then have a larger spend on getting a night crew to dig up the floor sink and P-trap, and complete tile work. Fewer back-ups reduces this risk.

What are the next steps you would like to implement?

We have many ideas on how to proceed with this project. One will be to present this data with our Construction Department and have the locking drain covers added for all new store openings. While we began our testing with 10 stores, our ops leadership partners have seen the benefits and requested additional stores. Currently we have roughly 50 stores with locking drain covers. My next goal will be to expand testing to an entire region. Shawn Coe’s restaurant career began in 1987. He has been employed by smaller chain restaurants in a variety of positions, from dishwasher to area director. His operational background, along with military experience as a C-5 crew chief, has helped him transition to working as a facility manager with Panda Restaurant Group. He supports Panda Inn, Panda Express, Uncle Tetsu, Ippudo, Hibachi San and Yakiya.

Visit Drain-Tech.com to shop Drain Locks

Will pouring salt down the drain help clear my drains

There are a lot of old wives’ tales about homemade solutions to cleaning out clogged drains. One of them we’ve heard is pouring salt down drains. Or flushing boiling salt water down drains.

We recommend you don’t dry this. It can be potentially dangerous to pour boiling water into drains. Sure you might find a website or two that suggests this, but there certainly is no consensus on this idea from professional plumbers. Remember that salt can be a corrosive element and copper pipes are the most vulnerable to corrosion from exposure to salt water. The copper reacts with the salt, which can change the structure of the material. Galvanized steel and cast iron also react to salt water exposure, but they are a little more resistant than copper.

We suggest preventing drain problems all together using the many products we offer. Visit Drain-Tech.com to buy today!

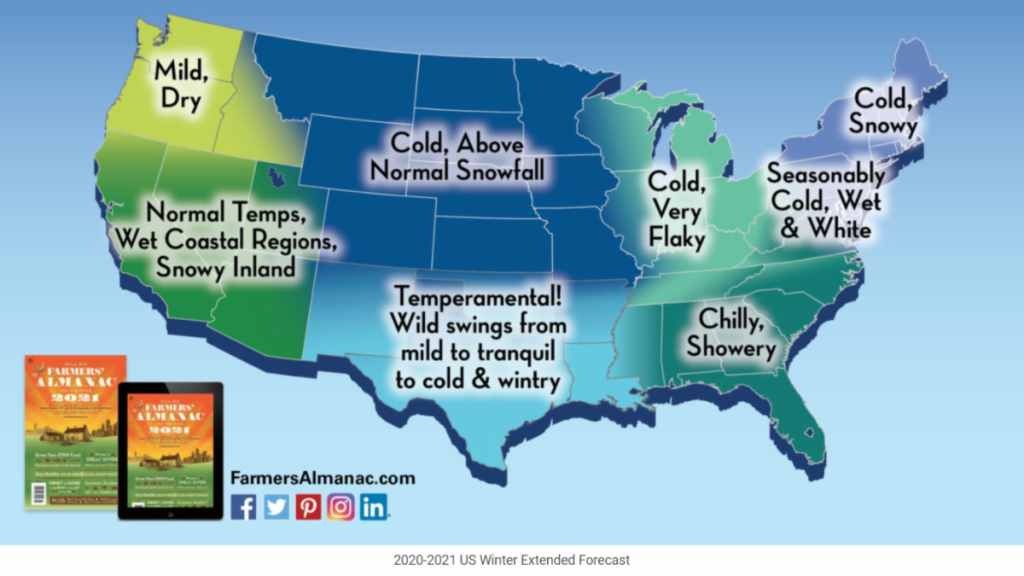

Why commercial buildings need a roof drain marker during snow season

Remember last year’s almost snow-free winter in the Northeast? Well, this year our prediction is very different, with the possibility of a blizzard hitting the Mid-Atlantic and Northeast states during the second week of February. This storm may bring up to 1-2 feet of snow to cities from Washington, D.C. to Boston, Massachusetts!

The Great Lakes region will get its fair share of snow but expect above-normal snowfall if you live in the western Dakotas, northern portions of Colorado and Utah, as well as Wyoming, Montana, Idaho, and central and eastern sections of Washington and Oregon.

Eastern Ohio and Kentucky can expect a significant snowfall in the beginning of February, and the Southern Plains are on target to receive copious amounts of snow, sleet, and rain later on that same month.

And for those living in the eastern half of the country, you may get clobbered during the final week of March, but what falls from the sky will depend on where you live-this storm will track from the nation’s midsection to central New England and bring a significant late-season snowfall to the north of its track, and showers and thunderstorms to the south.

I like knowing we have a part in making the roof safer for those on it, and those in it when drains are tended to. Marine grade aluminum alloy impervious to fresh water applications matched with a sub assembly comprised of a high grade stainless steel that’s been scientifically paired best compatibility for corrosion resistance. A quality product that delivers year after year, storm after storm. Built to last the life of the roof!

Due diligence pays big dividends A safer, faster, more efficient way to identify your roof drains. Reversibility of our flags for better functionality.

Visit our website to purchase today!

“Drain markers worked and are still working well. Not only did they come in handy during the snow fall we had this winter, but also helping the trades guys keep track of cleaning the debris from the drains.” Wesleyan University“This product solves the problem of roof drain locations on flat roofs. It is durable, easy to install and reasonably priced. I highly recommend Roof Drain Markers!” Superintendent of Facilities Berlin, CT

“I highly recommend the markers. It was easy to identify the drains in the snow, and the guys said they were really easy to install. They hold up great. The flag markers are strong but flexible. They’re worth the investment and look really good on the roof.” Tufts University

“Very pleased with the cost savings on keeping our roof drains clear of snow & ice this past year since we installed the drain markers. Easily locating them makes a difference. We highly recommend Roof Drain Markers.” Federal Realty

What is causing my drain clog?

Here are the top five causes for drain and sewer stoppages and how you can avoid your home or business problems.

1. Grease – You might assume that washing an oily pan in the sink is harmless, but grease is one of the top culprits for clogging. Fatty materials can stick in your pipes and prevent waste material from moving through them properly. Although you may not eliminate grease from your plumbing, you should try to reduce the amount of oil and fat you put down the drain. The best way to dispose of grease is to let the oil or grease cool and solidify. Once cool and stable, scrape the fat into a container that you can throw away. Please place it in a plastic bag to prevent leakage and then throw it in the garbage when it is full. Restaurants need to ensure they are using a properly installed Grease Trap or Grease Interceptor.

2. Fibrous Foods – You should not overestimate the abilities of your garbage disposal. Putting tough, dense food scraps like potato skins, celery, eggshells, pasta, beans, or stringy vegetables down the drain can disrupt the blades and block the pipes. Try to go easy on your garbage disposal to keep it functioning properly and avoid a drainage disaster. There are also garbage disposal alternatives that restaurants and commercial facilities should consider: https://www.drain-tech.com/garbage-disposal-replacement/

3. Soap Scum – Over time, your shampoo, conditioner, and body wash can coat the edges of your pipes, gradually narrowing them until water and debris can no longer flow through them. Also, soap scum can latch on to lose hair and make them more likely to form clumps. For an easy, natural way to clean your drain pipes, pour 1 cup of baking soda down the drain, followed by 2 cups of boiling water. Let the mixture work for about 30 minutes, then use a plunger to break up any clogs.

4. Hygiene Products – Feminine items, floss, cotton pads, dental floss, and other hygiene products can seriously plug up your pipes. Make sure you follow the instructions on the packaging and only flush things that readily dissolve in water.

5. Hair – Lathering your locks in the shower or brushing your hair over the sink could contribute to clogging. Hairs can tangle and form clumps that obstruct your pipes. To prevent this from happening, make sure you use a hair catcher in your shower drain and sweep hair from your sink.

Doing your part will help ensure water can move efficiently and prevent pipes from getting clogged.

Pouring grease down your drain is a slippery slope to sewer problems

You may think that pouring fats, oils or grease down the kitchen sink is no big deal. A victimless crime, at worst.

However, Michael Mitchell has gotten up close and personal with the unpleasant consequences of grease accumulating in Ottawa’s sewers. He can tell you that when it comes to what you pour down the drain, out of sight does not mean out of mind.

It’s Michael’s job to ensure that wastewater from your home travels efficiently through Ottawa’s sewer system to the City’s wastewater treatment facility.

When congealed grease builds up and gets lodged somewhere along the City’s 3,000 kilometres of sewer pipes, Michael knows it’s time to clear his calendar.

How does grease buildup affect your ability to maintain City sewers?

Grease buildup extends a one-day job into multiple days. It means extra staffing, contractor time, and bringing in all sorts of specialized equipment.

Typically, we clean pipes using high-pressure water, but when these grease build-ups happen, we have to use nozzle attachments with chain-cutters that rotate at high speed to scrape grease from the pipe walls. It takes a long time, but it gets the job done.

Are there any impacts on the pipes themselves?

Absolutely. Clogs aren’t the only issue. People might not know this, but grease corrodes and degrades the walls of a pipe over time. There’s also damage to the sewer system itself. When you have to replace a corroded pipe, that comes at a cost to taxpayers.

Visit Drain-Tech.com to help prevent drain clogs due to grease and solids!

What’s the worst grease-related incident you’ve seen?

I’ve seen a 24-inch pipe that was completely blocked with grease – the blockage was over eight meters long. Over time, the grease had completely eaten away the bottom of the pipe.

We use a remote-controlled robotic camera with mud-tires, called a CCTV robot. When we sent it into the pipe to have a look, it fell right through the hole. We had to excavate to retrieve it, which was another big job. The CCTV camera has a seriously dirty job. It will emerge from a pipe totally covered in grease. Better him than me!

Read the full story at: https://ottawa.ca/en/news/pouring-grease-down-your-drain-slippery-slope-sewer-problems-1

Commercial Foodservice Disposers – Cleaning, Maintenance and replacement

Disposers in commercial foodservice operations can help reduce trash-hauling costs by decreasing waste, eliminating food waste odors and decreasing labor by minimizing trips to the dumpster. Disposers often come with a control, sink or sink mount for existing sinks, stopper, water inlet hardware, back flow preventer, solenoid valve and flow control.

This equipment is typically installed in dish tables and pot/pan sinks as well as in vegetable prep, salad prep and meat prep areas. While a commercial disposer is more durable than the residential type and is capable of grinding more items, manufacturers still recommend using these units only for edible food waste. This is because some waste, such as corn husks and seafood shells, can clog drains…

It’s important to note that the disposal of any effluent into municipal wastewater (sewer) systems is typically governed under municipal by-laws/ordinances and enforced at the local level or through a regional municipal authority, in accordance with state and federal environmental legislation. These ordinances detail permissible limits of various materials and chemicals that can be present in effluent that is being disposed of into the municipal waste water system, and that ultimately need to be processed and treated at the wastewater treatment plant…

Cleaning and Maintenance

Operators should consider a variety of factors when it comes to the use and maintenance of disposers. First, do not use these systems to dispose fat, oil and grease. Also, batch feeding food waste into disposers blocks water, resulting in drain line clogs. For clogs, fill a 5-gallon bucket with cold water and run it through the disposer to push waste through.

After feeding product through the disposer, operators should allow cold water to run for 10 to 20 seconds to ensure small particles push to the main sewer line. Do not use hot water as doing so can melt fat and allow it to solidify and block the drain line. Keep plastics, silverware, straws and other non-food items away from the disposer to minimize jams.

Only use disposers with the appropriate food waste. Some food scraps, like potato skins, can build a layer inside the unit and dull the blades quicker. This also turns into a paste that drags motors down. Also, the higher the horsepower, the more volume the disposer can handle. It also helps to start and stop the unit as much as possible since the blades go in different directions when power is interrupted.

Many people think disposers have blades that spin, but this isn’t the case. These units use two weighted pieces on a spinning disk that throws food onto blades at the sides of the machine. Putting inappropriate food waste down disposers can clog the drain and grease trap, which is difficult to empty out…

Read the full article at: https://fesmag.com/products/guide/sanitation-and-safety/disposers/17910-disposers

Should I replace my Garbage Disposer?

The life expectancy of a disposer depends on the type of food it grinds, the food’s composition and how long the unit is in operation. Life cycles range from 3 years up to 20 years, with an average service life of 5 years for disposers that are cleaned and properly maintained.

Signs that indicate a disposer needs replacing include increased grind time, which can be caused by blades wearing out, motor failure or smoke, cracks, unusual or excess noise, and frequent repairs.

Commercial disposers that are 5 HP and up can be rebuilt, but with smaller units, too many things can go wrong, and it’s not worth the cost. Also, disposers with leaks in seals or shafts should be

But we suggest that you don’t replace a Garbage Disposer with another one that will just break again. Get the Garbage Disposer alternative: The A6 Wet Waste Interceptor!

Our Garbage Disposal Replacement Strainers (also called wet waste interceptors) separate solid food particles and water in commercial kitchen sinks. Dishwasher sinks, 3-compartment sinks, and other commercial sinks have to be able to handle large amounts of food waste which can cause drain backups and plumbing clogs. These wet waste interceptors improve drain line and grease trap efficiency.

These products are a great alternative to electric garbage disposals because they do not require electricity and do not have dangerous mechanical parts. These products are sometimes referred to as food scrap collectors, flat strainers, and garbage disposal replacement unites. Whatever you call them, make sure your plumbing problems are a thing of the past!

Learn more at: https://www.drain-tech.com/garbage-disposal-replacement/

FOG buildup turns Baltimore’s sewers into ‘Fatberg’

Cities

are constantly battling the FOG (fats,

oils, grease) buildup in their sewers. Baltimore recently found a huge buildup that they now are calling “fatberg”. The FOG was blocking up to 85% of the pipe in some areas. According to DPW officials, the fatberg removal will cost about $60,000. There are reports of a similar buildup in London’s sewer system that is taking weeks to breakdown. You can read the full story here: http://www.baltimoresun.com/news/maryland/baltimore-city/bs-md-ci-fatberg-20170925-story.html

Cities are cracking down on restaurants and foodservice facilities to take control of their wastewater. Drain-Net helps facility prevent FOG buildup with a wide range of products. We offer all types of strainers, grease traps, and all-natural drain defender products that help breakdown FOG. Please visit our website or contact us today for help.

City learns about drain maintenance

More and more cities are learning about the importance of drain line maintenance that Drain-Net promotes. Check out this excerpt from the Borneo Post:

More and more cities are learning about the importance of drain line maintenance that Drain-Net promotes. Check out this excerpt from the Borneo Post:

“Kitchen sinks at eateries here should be fitted with effective trappers or strainers to prevent food waste, including grease, from entering and eventually blocking drains, sewer lines and waterways.

“Grease, oil and fat as well as food residues can build up and harden over time. It will block the entire pipeline and drainage, leading to leakages of water, odour and contamination,” he told reporters during a community clean-up programme at Harmony Gateway near Carpenter Street here yesterday.

The activity involved some 20 students of SMK St Mary who were accompanied by their teachers.

“It is on arduous task for our men to constantly clean all the drains in this city,” he said.”

For grease traps, drain strainers, and more, please visit Drain-Net.com.